Smart Stockyard Management System | Steps Towards to a Fully Automated and Optimised Stockyard

MRA’s Smart Stockyard Management System (SMS) is a world leader in stockyard automation and optimisation for bulk materials handling and is ideal for coal, iron ore, bauxite and cement.

The SMS is being used to process 250 MTPA, representing 65% of Australia’s coal exports, including Port Waratah, the largest coal export terminal in the world.

OPTIMISED THROUGHPUT

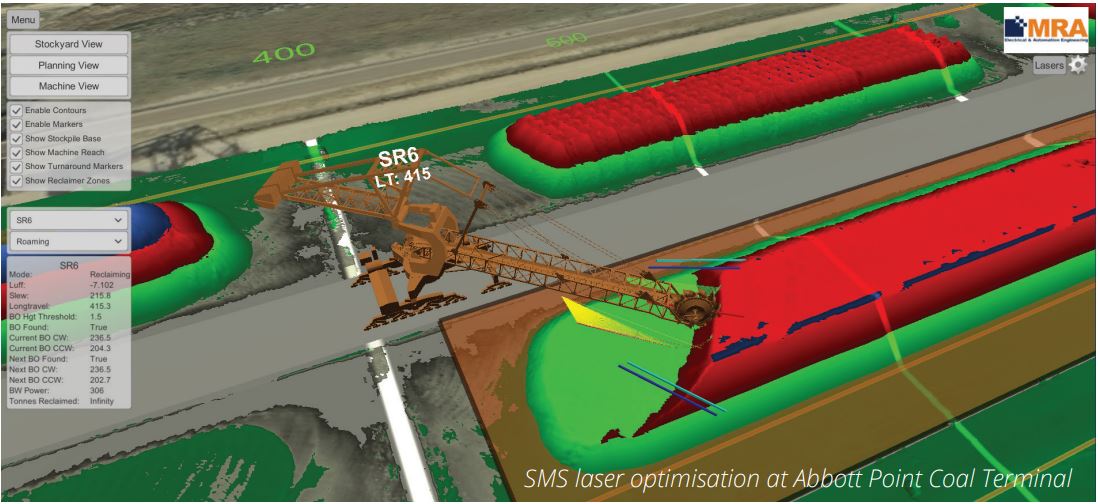

The SMS won the Australian Bulk Handling Award for Innovative Technology 2019 for its laser optimisation which increased production throughput at Abbot Point Coal Terminal by 11.3% across six stacker/reclaimers by using MRA’s SmartTurn. The cornerstone of the optimisation is a highly accurate, volumetric stockpile modelling system, which is enhanced with scanning lasers on each reclaimer.

Optimisation benefits come from an increased time-in-material with a reduction in slew cut turnaround times as it eliminates air digging. A Volumetric look-ahead feature uses predictive methods to reduce volume spikes which causes machine stress which lowers machine life.

MRA is an engineering firm based in Newcastle, New South Wales, that specialises in mine and port machine automation. MRA has developed the Smart Stockyard Management System that combines smart engineering and leverages the latest control and automation technologies from Rockwell Automation. The system can optimally manage and automate the inbound receipt and outbound delivery of mined material including, coal, iron ore and bauxite.

Find more information about the deployment of MRA's Smart Stockyard Management System here.