Hetech is investing in the growth of Australian Manufacturing

- Hetech's second manufacturing facility is now open.

- Now the owner of the state-of-the-art PCB cleaning machine - Ultra 2012LE.

- Developing young talent through Hetech's apprentice program

With a second manufacturing facility recently opened, Hetech is committed to investing in the growth and expansion of manufacturing in Australia.

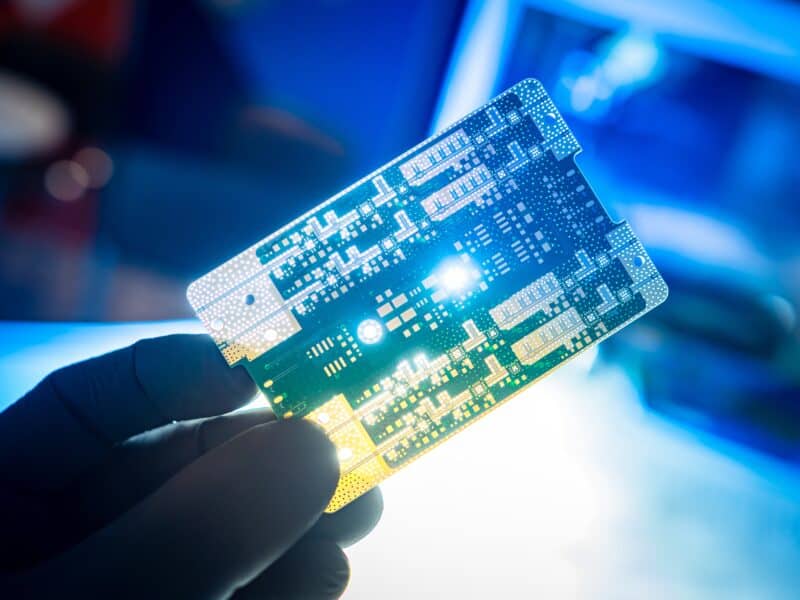

At Hetech we strongly agree with adopting new technologies and ensuring we have state-of-the-art machinery. Recently, we’ve purchased a PCB cleaning machine – Ultra 2012LE, Vapor Degreaser.

The Ultra 2012LE is a leader in the field of PCB cleaning. PCB’s are sometimes exposed to conditions like high humidity and extreme temperatures, they also need to last for sometimes decades, because of this it is vital PCBs function without fail.

With all of this in mind, what happens at the cleaning stage of production is vital, the Ultra 2012LE improves PCB reliability through the cleaning process. For a PCB to be reliable, a number of factors play a pivotal role, just some of the threats to its reliability include:

- Production contaminants such as dust and soils on a PCB run a risk of malfunction.

- Small PCB’s and complex PCB’s with multilayered layouts can be challenging to clean at the level required.

Hetech’s new Vapor degreaser machine provides state of the art cleaning for PCB’s. Vapor degreasing uses cleaning fluid immersion, combined with vapour rinsing and vapour drying, to clean PCBs down to the submicron range removing all types of residue.

The cleaning fluid used has a low surface tension allowing it to permeate the entire board, including under and in-between tightly-spaced and low-mounted components. Vapour degreasers recycle and reuse the cleaning fluid for hundreds of hours before the fluid is refreshed, making it a cost-effective and environmentally sound cleaning method.

Click here for more information and a short video explaning some of the features and benefits of the new machine.