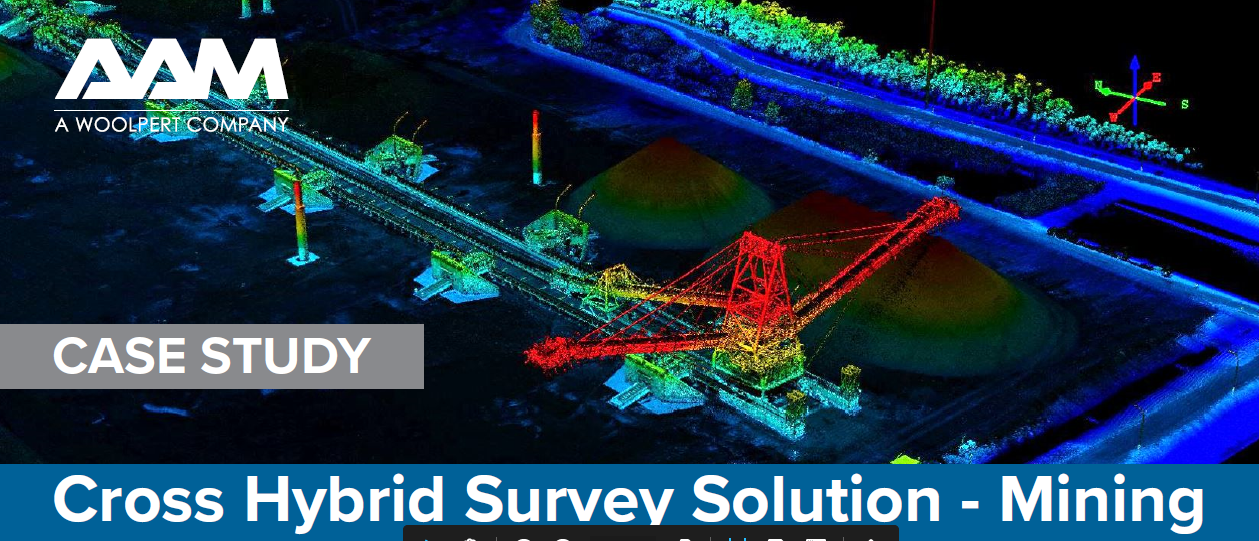

Cross Hybrid Survey Solution - Mining

Background

AAM are commissioned to complete recurring survey work for a mining company based in South East Queensland. Our client requires spatial survey information of three separate sites on a bi-annual basis. These sites are spread across a wide region and comprise of a mine, a coal handling processing plant, and a marine port. The LiDAR and imagery datasets that we capture are used to calculate stockpile volumes as well as audit reporting. The timing of the survey capture and spatial information delivery is critical. Spatial capture and data delivery must be completed within three days, otherwise operational downtime occurs at a cost to our client.

Challenge

At a recent biannual survey project for this client, AAM acquired spatial data for the mine site and the coal handling processing plant using a LiDAR sensor in a fixed wing, piloted aircraft on 30 January 2022. AAM used the Optech Galaxy PRIME sensor. We attempted to capture the LiDAR and imagery data over the third site which was the Port of Brisbane on the same day, however, were unsuccessful due to Air Traffic Control (ATC) denying access to this air space. We were under pressure to capture the required spatial data over the Port in order to meet our client’s 3-day deadline, however, were uncertain if we could use our piloted aircraft because of multiple factors: unfavourable weather conditions forecast for the coming days, further airspace restrictions were likely, and our aircraft had scheduled maintenance for safety and compliance.

Solution

AAM’s solution was to deploy our newly acquired LiDARUSA Surveyor32 UAV system and Sony a6000 camera, with the Innoflight Scanlift800 platform for this “Port” site. This solution was possible due to existing insurances and a pre-existing approval of our UAV / RPAS chief pilot to fly over the entire Port of Brisbane site, up to a maximum height of 40m AGL.

With our Unmanned Aerial Vehicle (UAV) [also called RPAV (Remotely Piloted Aerial Vehicle)] we managed to capture LiDAR and imagery simultaneously on Wednesday 2 February with a mission time of just 20 minutes.

The LiDAR and Ortho Imagery datasets were processed on Thursday, then volume calculations were completed by our spatial analysts. By Friday our Project Manager delivered the required spatial information to our client.

Results

Our client was delighted with the outcome and is keen to continue with this quick, flexible and accurate approach, especially since “we have always… have difficulty acquiring at the Port with ATC restrictions”. We see this regularly in the Mining sector. Timing is one of the biggest factors at play. This method has allowed us to complete within the date-specific timing requirements.

Read the full Case Study HERE.